The Future of Chocolate Production

The global chocolate industry is undergoing a profound transformation, driven by an increasing consumer demand for innovative products and sustainable practices. At the heart of this evolution lies the sophisticated machinery that transforms cocoa beans into delightful confections. This article will delve into the current ecosystem of mid-to-high-end chocolate equipment manufacturing and introduce LST Technology Co., Ltd. (LST), a leading enterprise dedicated to providing comprehensive solutions for chocolate food production and packaging.

The Evolution of Chocolate Equipment Manufacturing

The mid-to-high-end chocolate equipment manufacturing sector plays a crucial role in the confectionery industry. It is characterized by precision engineering, advanced automation, and a strong emphasis on quality and efficiency.

Key Trends and Impacts:

- Bean-to-Bar Solutions: As the demand for artisanal and single-origin chocolates grows, there’s an increasing need for integrated processing equipment, from cocoa bean roasting and grinding to conching and tempering.

- Automation and Smart Manufacturing: The integration of PLC and HMI control systems, automated production lines, and remote monitoring capabilities is vital for optimizing efficiency, reducing labor costs, and ensuring consistent product quality.

- Versatility and Customization: Manufacturers require machinery that can adapt to diverse product formulations, shapes, and sizes, including solid, filled, one-shot, and multi-component chocolates. The ability to customize equipment for specific production needs is highly valued.

- Sustainability and Energy Efficiency: A heightened focus on environmentally friendly practices is driving the development of more energy-efficient machines and sustainable manufacturing processes.

- Food Safety and Hygiene: Strict adherence to international food safety standards is paramount, including the use of food-grade materials (such as AISI 304 stainless steel) and certifications like CE and ISO9001.

These trends are transforming the industry by enabling higher production volumes, greater product diversity, improved quality control, and reduced operational costs. Manufacturers are increasingly seeking partners who can offer complete, integrated solutions.

LST: A Global Leader in Comprehensive Chocolate Solutions

LST Technology Co., Ltd. (LST Machine), established in 2009 and headquartered in Chengdu, China, has emerged as a prominent player in the mid-to-high-end chocolate equipment manufacturing sector. LST is dedicated to providing “overall solutions for chocolate food production and packaging” [1].

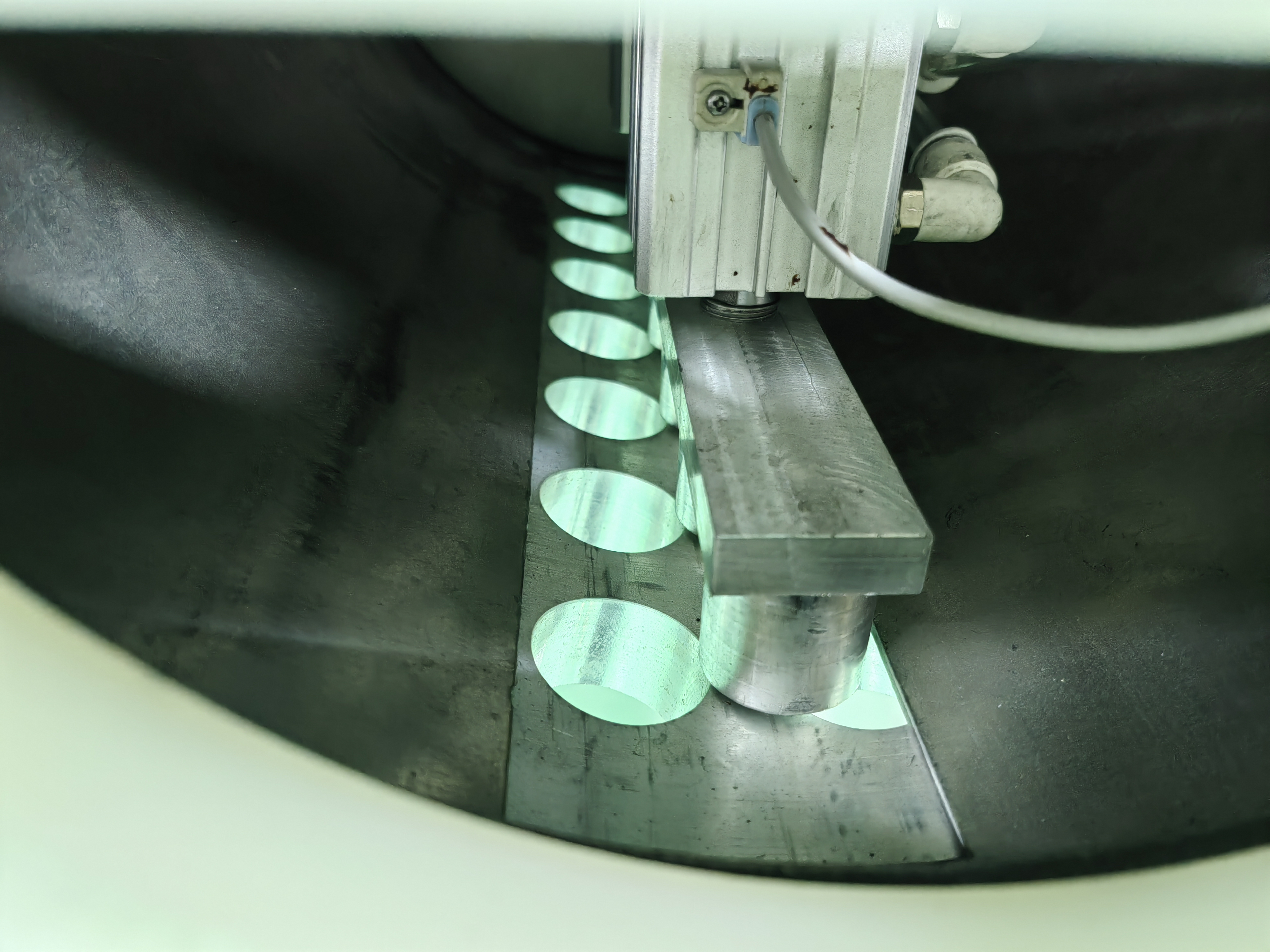

LST’s comprehensive product portfolio covers the entire chocolate manufacturing process, from raw material handling to final product molding and packaging. This includes cocoa butter presses, chocolate feeding systems, ball mills, conches, tempering machines, depositing and decorating machines, coating machines, cooling tunnels, and fully automatic production lines, among others.

LST’s Core Strengths and Strategic Pillars

LST’s leading position is built upon several strategic pillars that address the critical needs of modern chocolate manufacturers:

- Innovation and Advanced Technology: LST boasts a professional R&D team committed to continuous innovation, aiming to introduce “3 different high and new technologies” annually [2]. Their machines integrate advanced control systems and imported components, ensuring technological leadership.

- Commitment to Quality, Reliability, and Safety: LST emphasizes providing “high-quality, safe, and reliable chocolate production machinery” [1], demonstrating its commitment through the use of food-grade stainless steel materials and CE certification.

- Comprehensive Global Service and Support: LST offers OEM services and “global lifetime after-sales service” [1], including professional technical support and remote debugging capabilities, minimizing client downtime.

- Operational Efficiency and User-Centric Design: LST machines are designed for high automation and user convenience, featuring easy installation, disassembly, and cleaning, as well as space-saving designs.

- Product Versatility and Customization Capabilities: LST’s equipment is highly adaptable, capable of producing various chocolate types, and can be customized to create complete production lines according to customer needs.

- Competitive Pricing Strategy: LST claims to offer “the lowest price” [9], providing advanced equipment at competitive prices through direct factory supply and economies of scale.

- Strong Market Position and Credibility: Established in 2009 [1], LST has accumulated “2,563 satisfied customers” [1] and has extensive global sales, earning high ratings on third-party platforms.

Industry Outlook and LST’s Future

The chocolate equipment manufacturing industry is expected to continue its growth, driven by increasing global chocolate consumption and the demand for innovative, high-quality products. Automation, sustainability, and customization will remain key drivers.

LST is strategically prepared to capitalize on these trends, thanks to its continuous focus on innovation, strict quality standards, and comprehensive global support. The company’s commitment to providing advanced, versatile, and user-friendly machinery at competitive prices makes it an ideal partner for businesses worldwide seeking reliable and efficient chocolate production solutions. LST’s dedication to continuous improvement and customer success will undoubtedly contribute to its sustained growth and influence in the evolving confectionery landscape.